UXO Detection System

Adjustable Buried Bomblet Identifier

Overview

Key Challenges

Communicating with difficult client

Prioritizing deliverables

Detachable coil mechanism

My Role

Project Manager - Team of 5

White River Technologies

Thayer School of Engineering

Hanover, NH

Skills Applied

Project Managing

In-house Fabrication

Laser cutter

CNC Mill

Presentations to review board

Year

March 2019

About

Unexploded ordnances (UXOs) are weapons that did not detonate when intended. They can range from small bomblets to artillery shells. There are an estimated 110 million UXOs worldwide posing a threat to civilians and preventing land development.

White River Technologies (WRT) developed a device that integrates geophysical mapping technology to detect the exact geometry and depth of buried objects. With this device, UXOs can be detected in a safe and cost effective manner.

WRT's system was heavy, bulky, difficult to transport, and took weeks to manufacture, making it inconvenient for users and inefficient to produce. My team at Thayer designed a modified device that is lightweight, more aesthetic, easier to transport, and can be disassembled.

System Overview

Requirements

Assembly and Disassembly

WRT’s original design could not be disassembled. Using SolidWorks we modified the device so that each transmitter coil could be easily detached and reattached. In our design we took into account WRT’s in-house manufacturing capabilities and the materials they already order in bulk.

The device can be assembled in under 12 minutes and disassembled in under 7 minutes. This allows for convenient transport overseas and around field sites.

Time lapse of 7 minute disassembly

Weight Reduction

We were able to bring the weight of the device down from 74.8 lbs to 52 lbs for a total of a 30% weight reduction. We removed 9 lbs of unnecessary material from the frame without compromising its structural integrity.

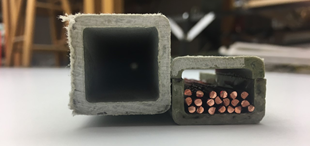

Our greatest discovery was that we could use aluminum coil instead of copper coil to reduce the weight by 13 more pounds. The electromagnetic properties of the system were not affected by the difference in coil material.

Material Analysis

In an effort to reduce weight we considered a variety of different materials including delrin, PEEK, fiber reinforced plastic, and nylon. We were looking for something non-conductive, cost effective, strong, durable, weatherproof, and lightweight. FRP met the majority of our specifications and was a material that WRT already orders in bulk for other projects.

Manufacturing Plans

We provided a detailed a manufacturing plan with drawings and step by step directions for WRT to follow when building their new device. Follow the link below to view the book we put together and see how we built the UXO Detection System.